this post was submitted on 17 Nov 2025

1213 points (99.1% liked)

People Twitter

8543 readers

1944 users here now

People tweeting stuff. We allow tweets from anyone.

RULES:

- Mark NSFW content.

- No doxxing people.

- Must be a pic of the tweet or similar. No direct links to the tweet.

- No bullying or international politcs

- Be excellent to each other.

- Provide an archived link to the tweet (or similar) being shown if it's a major figure or a politician. Archive.is the best way.

founded 2 years ago

MODERATORS

you are viewing a single comment's thread

view the rest of the comments

view the rest of the comments

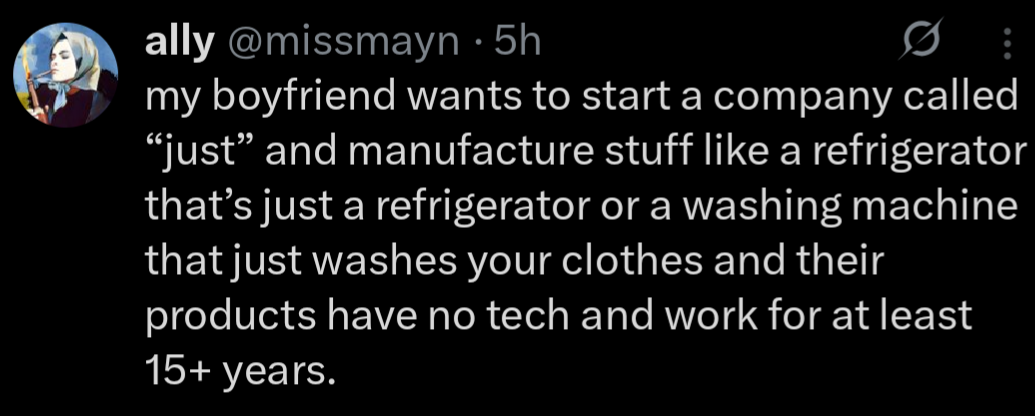

One thing to note is that planned obsolescence for machines is not something that is easy to do to the level that you're describing it.

Even if they use substandard materials at specific junctures with an estimated wearout time limit, there's always the chance that a manufacturing flaw can increase the time between breakdowns

I think a good follow-up plan would be something more like finding the parts that break down and then digitizing them and then contracting with a service like JLCPCB to manufacture those individual parts on demand.

You could probably start a fairly successful company on just that if you had the time and energy to get the whole process rolling.

A combination of a SLS 3D printer to make the parts out of metal, or, you know, really high-quality 3D printer to make them out of nylon or whatever plastic is necessary, and getting the appropriate springs and levers and bearings and everything to fill in the gaps, you probably could make a nice side business for yourself just custom making the parts that break down the most often for appliances.